Single Girder Overhead Travelling Cranes

The ABUS single girder travelling crane is our flexible crane for almost any application. Even in buildings with low ceilings effective material flow solutions can be achieved for loads of up to 16 t and spans of up to 39 m. Normally safety clearances below ceilings are not required for single girder cranes within this load range. This allows the optimal use of existing space or can save additional building height costs.

The ABUS single girder travelling cranes adapt to different building applications due to their various main girder connection variants. Favourable crane dimensions help to reach optimal highest hook positions. The main girder connection ‘version 3’ is the optimal solution for new factory buildings as this version offers the best side approach dimensions. If lifting height is the decisive factor then a single girder crane ELS with side-running trolley is the right choice.

The single-girder travelling crane is also a good choice for special solutions: The ABUS accessories and components offer specialised additional equipment to satisfy your requirements.

Robust rolled section girders form the crane girder of the ABUS single girder travelling crane ELV whereas ABUS single girder travelling cranes ELK and ELS consist of torsion resistant welded box girders.

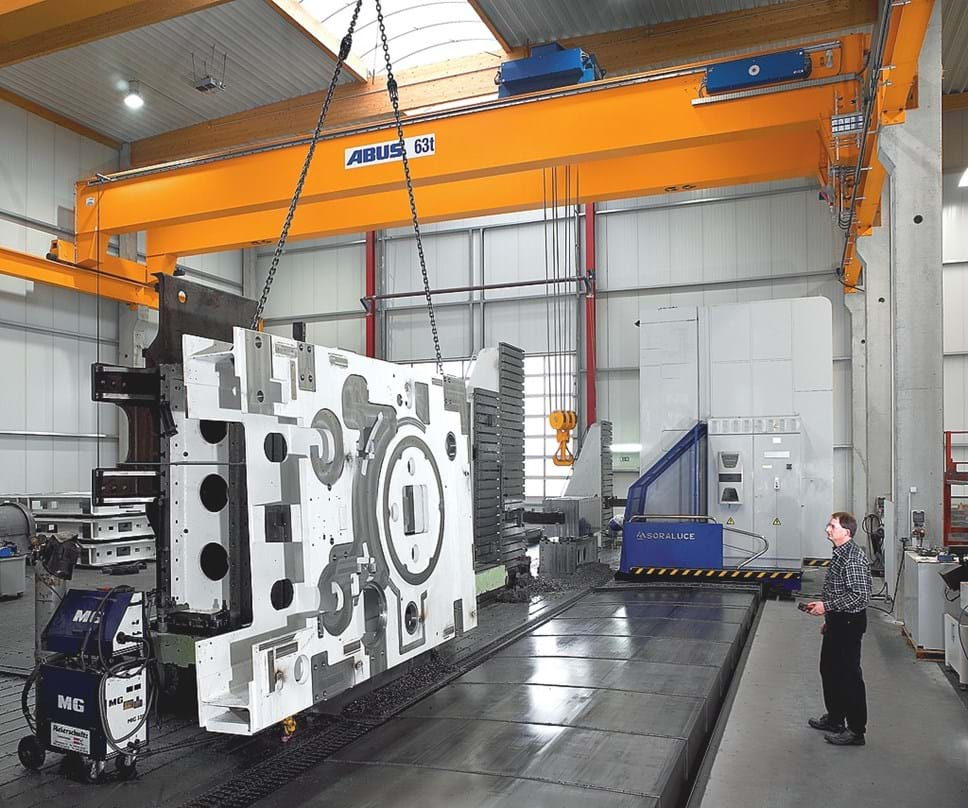

Double Girder Overhead Travelling Cranes

Double is stronger! If you need to transport heavy loads of up to 120 t across large areas then ABUS double girder travelling cranes are your first choice. Like all ABUS gantry cranes, they integrate well into different building structures, whether new or existing, thanks to various main girder connection options. ABUS double girder travelling cranes guarantee continuously high functionality, flexibility and ease of operation.

In addition, ABUS accessories and components offer a wide variety of specialised equipment for certain applications. ABUS double girder travelling cranes type ZLK feature welded box girders. All sections used for main girders and end carriages are computer-optimised for high performance and low weight, benefits that pay in terms of strength and cost efficiency.

ABUS double girder travelling cranes are available for spans of up to 40 m and feature the versatility needed for special requirements. For example, faster long travel speeds, maintenance platforms, crab units with walkways and auxiliary hoists are all features that can easily be implemented.

Underslung Overhead Travelling Cranes

Complex building conditions require specialised solutions, easily realised with ABUS underslung overhead travelling cranes. The gantry tracks are fitted to ceilings rather than free-standing or building columns. Thus best possible results are achieved even in tight spaces and difficult conditions.

ABUS underslung overhead travelling cranes make optimal use of the available building width by featuring very small side approach dimensions and bespoke main girder cantilevers. It is also possible to optimise the highest hook position by stooling up the main girder between end carriages.

ABUS underslung overhead travelling cranes offer load capacities of up to 8 t and spans of up to 25 m. The design versions DLVM and EDL feature rolled section girders. EDKs are designed with torsion resistant welded box girders. A comprehensive programme of accessories and components is also available for ABUS underslung overhead travelling cranes.

Single Girder Wall Travelling Crane

ABUS wall travelling cranes have a track to themselves underneath the big overhead travelling cranes. This enables you to transport loads within individual production areas independently from the cranes on the higher level.

ABUS wall travelling cranes are designed with load capacities of up to 5 t and with spans of up to 12 m.